915MHZ Microwave Plasma

CVD Reactor Optimized for

Single Crystal Diamond Growth

Chemical Vapor Deposition

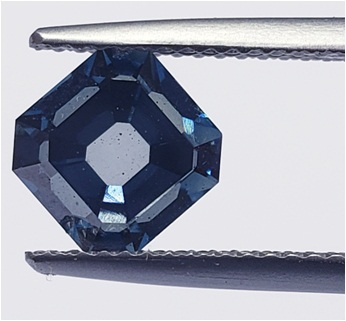

Type IIA Monocrystalline &

Polycrystalline Diamonds

Medical Applications

- Scalpels - Eye Surgery and Laser Based Coagulation

- Knives - Ultramicrotome

- Ultraprecision tool for milling Intraocular Lenses

- Pharmaceutical - Water Purification

- Ramen Laser - Window

- CO2 Laser - Window

- Radiation Dosimetry

- Sensor for Magnetocardiography

- Fluorescence Imaging

- Medical Grade Nano Diamonds

- Prosthetic Limbs Coating

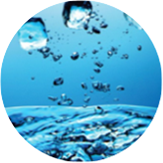

- Water Purification - Disinfection in Multi Stages

(Refractory Chemicals Electrodes)

Optics

- Laser windows

- Infrared windows

- Lenses

- X-ray windows

- ATR units

Industrial

- Oil and gas drill bits

- Precision machining

- Wear resistance

- Wood Machining

- Grinding and Polishing

- General Engineering

- Road Maintenance

- Stone and Concreate Processing

- Mining, Tunneling and Drilling

- Diamond Composite Materials for Industrial Use

Semiconductors

- Radar

- Communication Satellites

- Diodes

- Switches

- Ultra Pure CVD utilizing nitrogen vacancies for Quantum Computing Devices

- Cellular Communications Towers

- RF Amplifiers

Semiconductors

- Radar

- Communication Satellites

Optics

- Laser windows

- Infrared windows

- Lenses

- X-ray windows

- ATR units

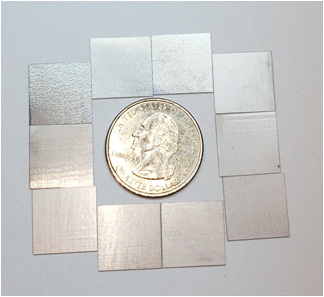

Thermal

- Heat spreaders

- Laser sub mount

- X-ray sub mount

Industrial

- Oil and gas drill bits

- Precision machining

- Wear resistance

Water Purification

- Electrodes for water purification

Sensors

- Radiation Sensors

- Fluorescence beam monitors

- Ionizing radiation detectors

Quantum Computing

- For faster data processing and secure communication

Medical

- Radiation detectors for eye cancer therapy

- Surgical scalpel

- Medical Grade Nano Diamonds

| 915MHZ CVD REACTOR | ||||||||

|---|---|---|---|---|---|---|---|---|

| Chamber | Reactor Chamber Type | Cylinder | Material | AI/SS | Vacuum Seals | Viton, Silicone | Water cooling walls | yes |

| Vacuum System | Typical Operation Pressure range, Torr | 1-30kPa | Base Pressure, Torr | 10-200 | Vacuum Leak Integrity, Torr/sec | <3*10^-5 | Vacuum Type pump | Hydrocarbon |

| Vacuum filter | Yes | Turbo Vac | Optional | |||||

| Microwave Generator | Microwave frequency | 915MHz | Microwave Output Power | 3-25KW | Impedance matching (tuner type, automatic, etc.) | Manual | Protection | Yes |

| Reflected power microwave detector | Yes | Water cooling | Required | |||||

| Substrate Stage | Substrate material | Moly | Stage Material | SS | Cooled | Water Cooled | Heated | No |

| Stage Size | 85mm - 230mm | Substrate Holder | Moly | Deposition Area | 100mm-200mm | Manual change the height | Manual | |

| Auto Z-axis motion | Recipe Driven | |||||||

| Process Gases | #1, H2 sscm ? | 2000 or User Select | #2, CH4 sscm ? | 400 or User Select | #3, ?? | User Select | #4 | User Select |

| Purge port | Yes | Mass Flow Regulators | 4(Standard) or More Optional | |||||

| Cooling system | Cooling type | Water | Water type | Distilled | Temperature of Cooling Water | Above dew point | ||

| Electronic & Software | Screen | Touchscreen | UPS | Optional | Auto recipe-driven control system with run-based data collection and safety interlocks | Yes | Additional software, process control, etc. | Remote monitoring/control |

| The power supply system | Emergency Stop Button | Yes | ||||||

| Control Temperature | Pyrometre | 1 | ||||||

| Growth rate | For Single Crystalline Diamond | 10 to 30 Micron | ||||||

| OPTIONS | Motor driven Z with High precision stepper motor | yes | H2 generator | On Request | H2 palladium purifier | On Request | DI water Purifier | On Request |